Air Compressor Remote Monitoring System

To ensure the normal operation and preventive maintenance of the air compressor, InHand provides a (cloud + end) air compressor remote monitoring system solution with InRouter900 IoT gateway and Device Networks Cloud.

Background

As large general-purpose mechanical equipment, air compressors will inevitably generate a large amount of after-sales maintenance and fault handling requirements during long-term use, and the power consumption and maintenance costs are relatively high. When a fault cannot be timely fixed, long downtime will bring huge losses to customers.

In order to ensure the normal operation and preventive maintenance of the air compressor, InHand provides a (cloud + end) air compressor remote monitoring system solution. The solution uses InHand's industrial smart gateway InRouter900 on field end, which has high performance, high reliability, comprehensive security and wireless services, to provide high-speed path for device informationization in the true sense. InHand Device Networks Cloud is used as the IoT cloud, with low-cost, high-efficiency background data storage technology, flexible functionality, scalable and upgradable architecture, enables centralized access management of front-end connected devices. The solution helps to rapidly achieve intelligent monitoring, operation and maintenance management, enable more economic and efficient management of air compressors, reducing energy consumption and improving business efficiency.

Solution

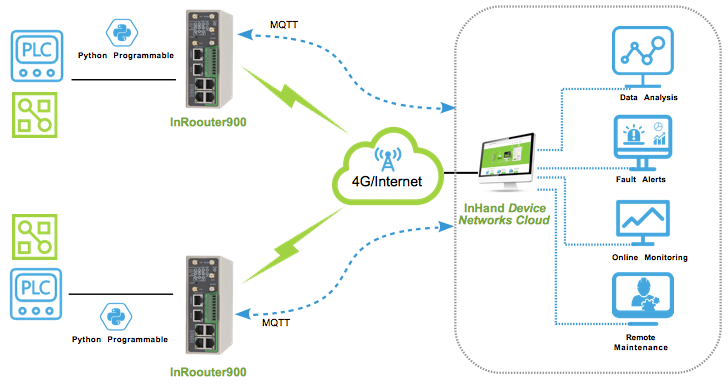

The system consists device layer (collecting controller data via edge computing gateway) and cloud platform layer (device cloud).The edge computing gateway InRouter900 collects field controller and sensor data, intelligently upload the data with local cache mechanism, ensuring data reliability and real-time while reducing network costs. With Internet access, the compressor's on-site operation data: pressure, temperature, load time, alarm status of components, etc. are transmitted to InHand cloud platform in real time through encrypted transmission, authorized users can monitor the real-time air compressor operating status, alarm and fault information through Web or mobile phone app anywhere anytime; or preform remote monitoring, management, debugging, preventive maintenance, etc. through the PC client, reducing and optimizing fault processing time and communication costs and upgrading service level.

Key Functions of InHand Device Networks Cloud

- Internet Access of Device

Adopting InHand industrial-grade wireless smart gateway to access the Internet - Data Collection and Analysis

Data pre-processing using the gateway's open development computing capabilitiesAnalyze node health status with big data computing power - Fault Pre-alarming

Using machine learning to build expert system modeling to predict node failures - Operation and Maintenance Scheduling

Establish operation and maintenance process, and generate maintenance dispatch order with the alarm analysis results - Online Monitoring

B/S architecture, support convenient web access and workflow processing - Mobile App

Monitor equipment operating status and maintenance order processing from mobile terminal

Advantages

- Use InHand's "cloud"+"end" solution, to greatly shorten debugging cycle and reduce front-end deployment work

- Allow access of massive amount of equipment, saving equipment operation and management costs as well personnel management costs

- Save data traffic, routers upload data to the platform via MQTT, which is advantageous over traditional VPN

- Convenient for maintenance, just require end configuration, support remote web access

InRouter900 Industrial Smart Gateway

- Dual link backup: support link backup, VRRP technology, providing faulty line link redundancy

- Passed CE, FCC, UL, PTCRB, CCC, Verizon Wireless, and AT&T certification

- Fully industrial-grade design, to provide reliable, secure and stable data transmission links for unattended sites

- Can realize edge computing through Python development for data analysis and processing, customer can customize smart logic processing, preprocessing data on site

- Built-in GPS module, positioning more accurately than with base station data

- Microsoft Azure IoT certified