Urban Heat Supply System

In an era where low-carbon economy is advocated, it is important that energy supply is highly efficient. In light of this, InHand Networks offers a remote networking monitoring solution for heat supply using its IG902, which enables users to oversee the operation status of the heat supply system, acquire accurate and effective data, thus ensuring secure and stable operation of the devices.

Background

In winter, the city is faced with rising demand for the quality of heat supply. In an era of energy scarcity, it is urgent to improve heat supply work while saving energy. As the heat supply network is expanding with dispersing worker stations, it has become challenging to monitor the operation data, control and manage the heat network for better economic efficiency, and better utilize heat resources. In light of this, InHand Networks offers a remote networking monitoring solution for heat supply, which can oversee the operation status of the heat supply system, provide accurate and effective data for the heat department, improve the efficiency of heat utilization and ensure secure and stable operation of the devices.

Solution

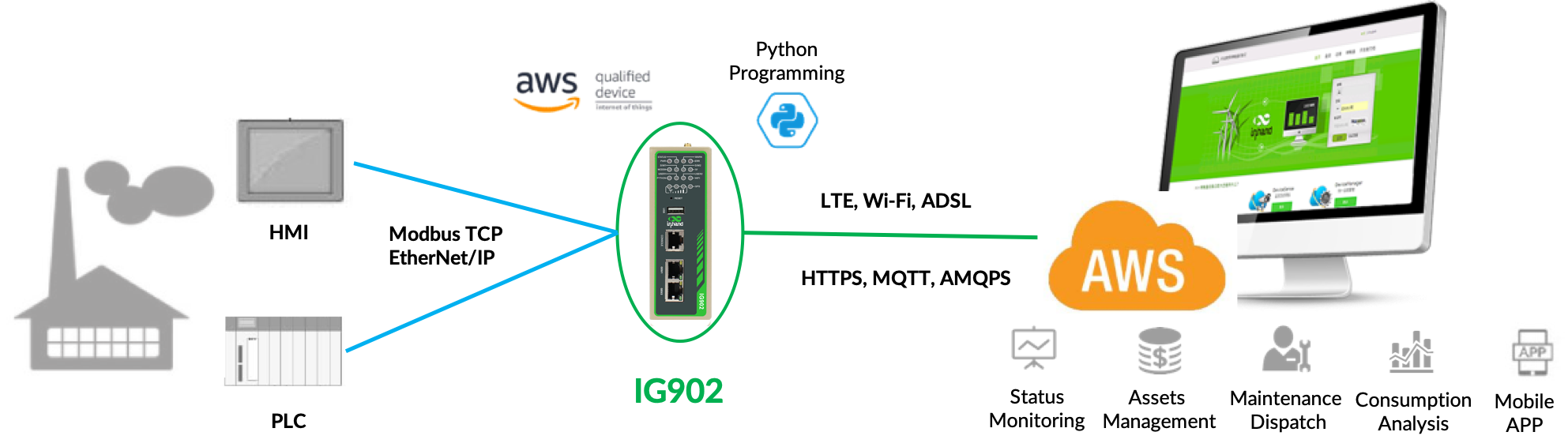

The on-site IG902 edge computing gateway is connected to the PLC and HMI of the heat supply station?s control system for data collection, and connected to the cloud platform via MQTT protocol to upload data of heat exchange stations.

The remote platform for the smart heat network features monitoring of heat exchange stations, alarming records, statistical analysis, report management, system management, BI demonstration, station alarm, etc. The B/S architecture platform can be accessed via PC, mobile phones and tablets.

The platform can manage operation status data of heat supply stations, such as inflow water temperature, outflow water temperature, inflow water pressure, outflow water pressure, operation status of the compressor, leakage, temperature threshold value, activated status, alarm, etc.

The solution helps effectively and intensively manage different nodes in the heat supply network, overcoming the difficulty of manual on-site management by the traditional heat supply network. The control parameters can be uploaded to the cloud system anywhere at any time, so that faults can be better detected and eliminated. This reduces the user's waiting time and loss due to faults, cutting the after-sale costs of device operation, and enhancing client satisfaction.

Why InGateway902?

- Highly reliable and uninterrupted network access

- Powerful edge computing capabilities

- Custom Python-based development platform

- Multiple industrial protocols

- Supports Microsoft Azure and AWS Greengrass cloud platform

- All industrial design, EMC grade 3